Hi developers! I just took a look at the “getting started” section and I must say I’m a bit disappointed with some of the statements/claims in the Rhino section.

However, first I’d like to say that I really appreciate all the work you’ve done for bringing 3D-modelling to the iPad. Shapr3d is a nice and intuitive tool and you are obviously listening to your customers. The program is also getting better all the time. This is all great!

Now to the strange part I was referring to. In the mentioned section you claim that “… in most cases models created in Shapr are more accurate than Rhino, thanks to the underlying industry standard modeling engine (Parasolid).” I’m sorry, but this is not true. Perhaps nice advertising, but not true. Rhino is as accurate as your computer and floating point mat is. If you have inaccuracy in the Rhino-model it’s most certainly due to user error (of an inexperienced user) and has nothing to do with the accuracy of the program. It’s true that Rhino allows you to change a lot of parameters witch puts the responsibility to the user. For instance… modelling tolerance is adjustable in Rhino (in Shape it seems to be hardcoded to 0.0001 units). The possibility to change different parameters opens possibilities that you don’t have with other programs, but also means that you need to know what you’re doing. That’s only one example, but you get the picture…

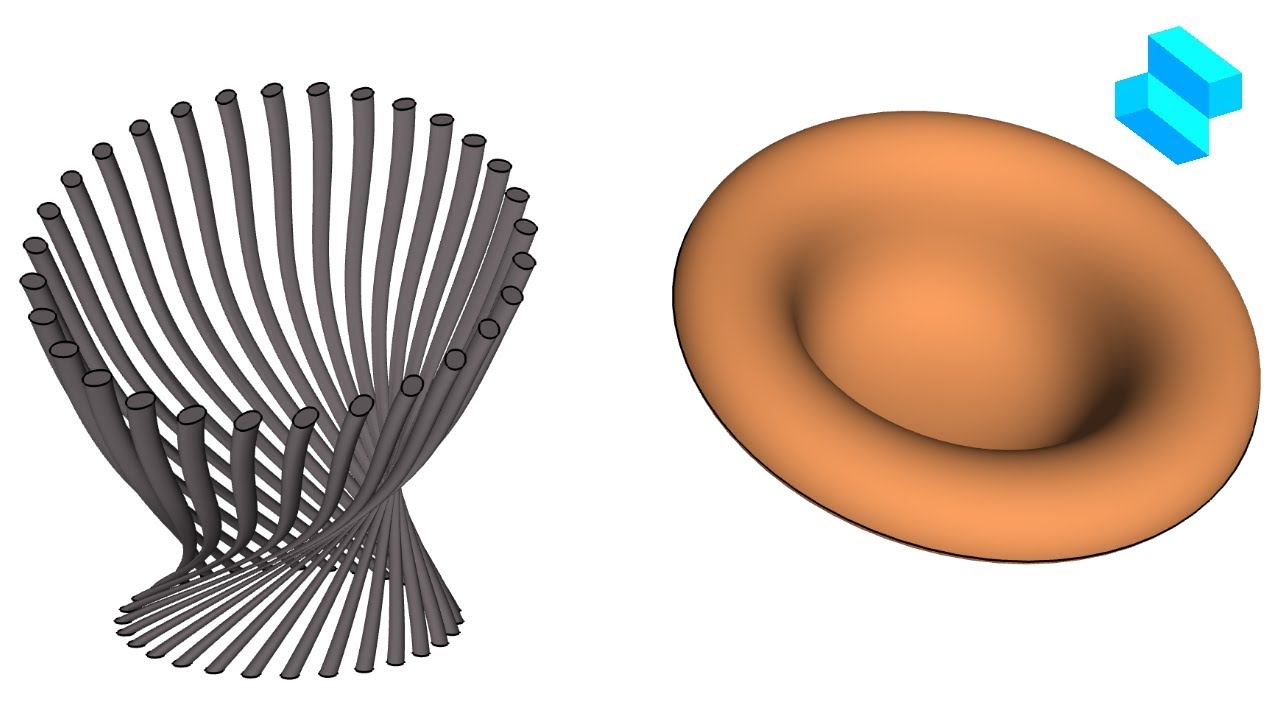

And this… “This means that with Shapr it is much easier to create manufacturable, watertight models.” If we’re talking about simpler, boxy models - then yes - this is true - for a beginner! On the other hand - if you’d like to create some advanced, free form models you might be totally out of luck…

Lastly… This is true, but doesn’t tell the whole story: “… Rhino is a surface modeling tool, Shapr is a solid modeling tool.” Well yes, in principle - but Rhino is actually both!

However, I still like Shapr for what it is - and hopefully will be - but I would have hoped that these inaccuracies in the text (pun intended  ) wouldn’t have been there. I still like to be part of the development and make Shapr even better

) wouldn’t have been there. I still like to be part of the development and make Shapr even better  So, thank you and I’m sorry…

So, thank you and I’m sorry…

Philip

(Rhino-user since 1997)

Btw, meanwhile using the replace face tool you can use your surfaces created in Rhino to replace faces in shaper

Btw, meanwhile using the replace face tool you can use your surfaces created in Rhino to replace faces in shaper