I like this design and thought it is easy to build but …… fail to do it many times and not even close particularly the turning point with big circle alike integrated, can anyone give me some hints?

The circles are easy enough. Here’s a quick example.

I drew a half circle and revolved it to get a ball. Then I made a sketch to cut the sides off the ball… Then shelled the ball and made another ball to fit inside it. I could instead have just subtracted the small ball from the big one.

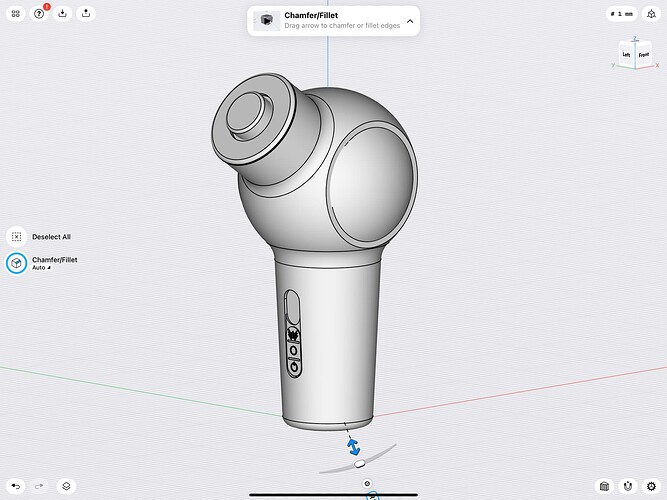

Then I drew two circles for the handle (I wasn’t sure if it’s a circle handle in your photo but the procedure is the same for any shape you draw). I Lofted the two circles into a handle shape and then Unioned the handle and outer ball and then chamfered the join line between them.

I hope that’s of some help to you.

Some work on the head part. Then a cutout for the switch and then I extruded switch parts and raised symbols. Some chamfers to finish off the geometry.

Main work done. All took about 30 minutes. I’ll add materials in Visualisations shortly.

A quick play with materials in Shapr3D Visualisations (anodised metal, glossy abs, transparent polypropylene, and felt) and some renders in the environments.

And an AR shot of the product on my bedside locker. It’s probably not to correct scale as I don’t know what the product is, but it’s nice to see in AR.

It was fun making it anyway ![]()

Thanks a lot of your illustration, this is how I tried, it is the transaction area between the handle and the circle that I couldn’t manage, that is very smoothly integrated all together.

I think you did well there Raymond. ![]()

But I still couldn’t manage how to build that perfect smooth surface between the circle joint and the handle…… there must be some other way around……

Have you tried applying a G2 fillet?

I did but didn’t help much. Besides I observed the centre of ball is right at the centre of handle and ball size couldn’t be too small but couldn’t be too large…. It may be the size of ball and size of handle are all calculated precisely…… anyway I surrender ……

Here’s an alternate approach. Note that the sizes and contours are not exact but meant to show a different construction method.

Thanks for giving such good idea, I suppose it is the correct approach

That turned out very well indeed.

I agree with @Stephen that it turned out well.

FWIW, here’s a variation of my previous model. I made the horizontal barrel shaped body asymmetrical so that it intersected with the vertical bodies more imbedded at the front. Then I did the fillet in two steps which made for a smoother fillet overall.

You thought that through very well Mike, all credit to you.

@Stephen, thanks. Always glad to help out (if I can).

Thanks for your advice Mike, that was exactly how I built this model now

Most welcome. Glad to help.