Hi There, I need some help as im fairly new to CAD in general. I am trying to create an engine cowl for an aircraft. Effectively trying to create the shape so that I can then take sectional profiles that can be sent to a CNC router service, to cut the profiles, that I can later stick together and fill with foam from which to make a plug for fibre glassing.

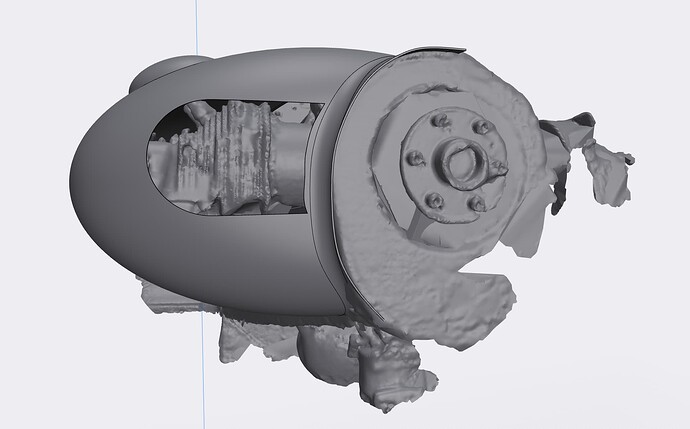

However, the bowls around the engine cylinders are quite difficult as they are not symmetrical, I have tried a few different methods. I have tried to revolve a shape around an axis, which wasn’t suitable. I have also tried to draw various different profiles and then loft between them but this ends up looking too blocky.

What ever shape is finally created, I would also like it to be hollow so that I can ensure clearances between the cylinders, walls, spark plugs etc.

Any Ideas on the best work flow. As you can see below images, the original engine cowls that I am not trying to fully reproduce, but that in general is the overall idea. And then you can see two of my progress attempts but they’re very blocky.

Any help or advice on best tools to use, or a kind of workflow guideline would be greatly appreciated.