Goal: Bend a flat headband model into a constant-radius arc without rebuilding geometry.

Flat model (current):

-

Single solid “strip” with uniform thickness (≈10 mm), height 538 mm, length ≈320 mm.

-

Beveled/chamfered ends.

-

Designed flat to keep window cutouts dimensionally true. **This is why Im asking because as you see Ive built a curved model, with construction plane, and window wont stay true. I very well could be doing this incorrect as well. I welcome all corrections.

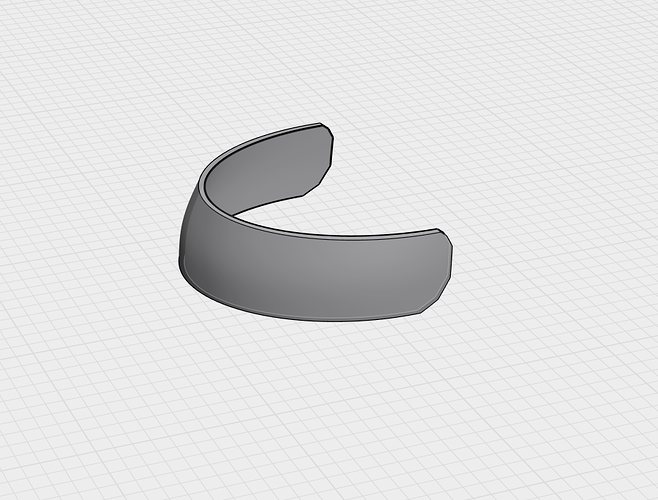

Target shape:

- C-shaped headband segment matching a head curve , constant thickness, end bevels preserved—like in my second image.

What I’m trying to do in Shapr3D:

-

Use a non-destructive bend so overall arc length stays the same and features don’t warp.

-

Ideally: Deform → Bend on the whole body, bend axis along the long centerline, and keep “preserve thickness” behavior.

If Bend isn’t the right tool:

- I’m open to a Shapr3D-native workflow that keeps dimensions (e.g., a reliable bend method, or a recommended workaround that avoids fully rebuilding.

Screens attached show the flat part and the curved result I’m aiming for. Any tips on the exact Bend setup (axis placement, angle vs. radius, best practices to avoid end distortion) would be awesome. Thanks!